WASHERS

NEW DRUM BEARINGS & SEALS

Many washers receive new drum bearings and seals. We remove the tubs, bearing housing, and press in new bearings/seals. Shaft collars are replaced too. Trunnions and baskets are sent out or replaced if there is any sign of excessive wear.

NEW MOTOR BEARINGS

We remove the whole inner motor assembly and press on new bearings. We also inspect coils and remove dust. We want your machines to last!

FRESH PAINT

Each section of rust on components and frames is sanded out and covered in a fresh coat of matching paint.

NEW DOOR GASKETS

Door gaskets are always replaced. Old gaskets leak and hold mold. Needless to say, they look great when they’re new.

NEW SOAP LIDS

Soap lids often hide mold, mildew and soap scum. So, they are automatically replaced with new.

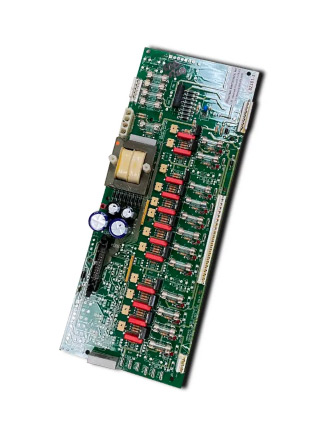

COMPUTER REPAIR

We send out faulty computer boards to be rebuilt or replace with new. Boards are then reinstalled and of course, backed by a warranty

NEW DRAIN VALVES

All washers receive new drain valves. Good or bad, these are always replaced.

NEW WATER VALVES

Another wear component. Valves are replaced with new. In some cases OPL machines will receive valve rebuilt kits.

NEW TOUCHPADS & DECALS

You can expect washers to run and look good. Touchpads are always replaced.

Machines receive new decals and overlays too.

BELTS

All machines, young or old receive new belts. Easy to do when the machine is removed, it’s a must.

THE FINISHED PRODUCT

Washers in reconditioning are not limited to these repairs. Once completed, the washers look and run great. They are inspected and tested yet again to assure the customer will receive them problem free. These are investments, so we want our customers to have great machines and maximize profitability

DRYERS

DRUM-OUT LINT REMOVAL

First and foremost, all panels, lint screens, computers and drums are removed. Dryers are dust machines, so we disassemble and remove all the lint that’s packed away and out of sight. Whether it’s in computer compartments, rear lint compartments or drum beater-bars, all the lint is removed. This extends life and prevents fires.

PAINT TOUCHUP

We want dryers to not only run great, but look great too. Sides can be patched and painted along with any other scuffs or scratches. Often times, complete panels are powder coated.

ROLLERS

Reconditioned machines receive all new drum rollers.

BELTS

All dryers receive new belts…automatically.

TOUCHPADS, OVERLAYS & DECALS

All stack and single pocket dryers receive new overlays, decals and touch-pads. A small touch, but this makes machines look like new.

IGNITION BOXES

Every dryer receives a new ignition box to assure your machine will ignite every time.

BEARINGS

All stack and single pocket dryers receive new overlays, decals and touch-pads. A small touch, but this makes machines look like new.

FINISHED PRODUCT

Cleaned, polished and tested, completed dryers are sure to please .

GET IN TOUCH

Trusted by the industry since 2010, we specialize in providing top-quality refurbished laundry equipment for businesses of all sizes. From hotels and laundromats to schools and homes, we’re your one-stop solution for reliable commercial laundry equipment.